Palomar Mountain Home Construction ProjectJim Hamerly, owner-builder and grower of trees |

||

It has always been our dream to build a home in the woods at an altitude above 5,000 feet, where we could experience the four seasons in a semi-remote location full of wildlife (deer, wild turkeys, etc.). We've developed and recently completed (November 2006) a home high atop Palomar Mountain, California. Using the latest construction materials, the home is an off-grid, all solar powered home. We tap the subterranean basement to cool the home in summer via a whole house fan. Of course, we have wireless LAN's as well as CAT6 1000Base-TX (Gigabit Ethernet, and ready for 10 Gbit LAN) throughout. Novel applications include the use of Structural Insulated Panels ("SIPs") and triple-junction, amorphous silicon photovoltaic laminates ("solar cells"). |

I've always been interested in solar energy conversion: I did early fabrication of crystalline solar cells at MIT in the late 1960's, polycrystalline silicon at UC Berkeley in the early 70's, musing while other solid state physicists laughed at Stanford Ovshinsky for his research into amorphous silicon. He got the last laugh, and my cells today are made with his amorphous materials. He is also the inventor of nickel metal-hydride (NiMH) batteries, among many other things. Numerous people have asked me to chronicle some of the pitfalls that I have encountered as a first-time owner/builder. You can read about some of them here. Caution: This home is at 5415 feet above sea level, which means your wristwatch will run approximately 0.000000015 seconds (15 ns) faster per day than at sea level according to Einsteins' General Relativity. Light travels about 15 feet in that period of time, if that helps. Air pressure is about 82% of that at sea level, and water boils at a lower temperature (94.6 degrees Celsius instead of 100 degrees Celsius). Students of Operations Management take note: Spaghetti takes longer to cook! |

|

|

Although we are not officially LEED certified (I didn't want to pay the fees), we meet or exceed the LEED specifications in almost all areas, including ones they haven't yet incorporated. Read here. | The LEED (Leadership in Energy and Environmental Design) Green Building Rating System™ encourages and accelerates global adoption of sustainable green building and development practices through the creation and implementation of universally understood and accepted tools and performance criteria. Read about our compliance here. |

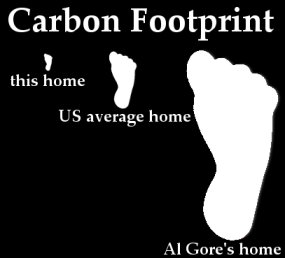

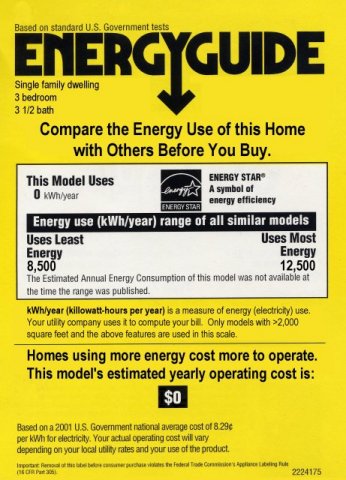

Check the Energy Guide at right from Hamerly Electric, sole proprietor, for our all solar, off-grid home. And check out our carbon footprint, below:

New! You can now buy carbon credits directly from us! Click here. |

|

|

July 14, 2004: Following two summers of significant tree clearing and wood splitting, and lots of measurements to position windows and such, the main construction area is staked out. Thanks to neighbor Bill McKinley for help provided, and to professional logger John Hodge who taught me how to drop trees safely. I listened and watched very carefully. I took out mostly black oaks ("widow makers"), some as large as six feet in diameter, and gave away about 100 large truckloads of wood in the process. I am now raising and planting Colorado Blue Spruce and Giant Sequoias (very difficult!) to augment our thousand or so of cedar, pine, fir trees and California Oaks. See here. I developed an immense appreciation of how difficult it must have been to clear land in the18th and 19th century without power assists. It is inconceivable to me how rugged those folks must have been. Architect: Roger Duguid |

|

|

| Groundbreaking on July 22, 2004. Photo taken on August 7, 2004: Dutch Bergman uses his dozer to dig the basement foundation. In spite of rocks nearly everywhere else, not one rock is hit. PTL. |  |

|

| August 14, 2004: The basement is prepped with the start of nearly three miles of re-bar that will be used in the home. We break several rebar benders on the unusually heavy 5/8" rebar. |  |

|

November 14, 2004: Following lots of arm wrestling with the county:

a building permit is issued. Within 48 hours, Don Mendenhall pours the concrete foundations (140,000 pounds) using one cool pumper with a wireless joystick to direct the concrete. Extra kudos to Alan Serry for extra careful "sequencing". |

|

|

| December 21, 2004: Trying to beat the winter, Marshall Heaton starts on the block construction walls before the winter snows fall. The lower courses are 12", the upper 8" block with miles of rebar inside. Still about 50% of block to be done. |  |

|

| January 15, 2005: Following nearly 30 inches of rainfall followed by snow, the project takes a temporary winter stall. I'm getting pretty good at pumping the water out of the basement by now. Another 30 inches of rain will fall before spring. |  |

|

| January 23, 2005: Most of main part of home block wall completed, the two side "L's" yet to be done. Also, water tanks, pumps, well, and fire hydrant all completed by Dan Stehley. The two 5,000 gallon water tanks in the distance are filled and ready to go. |  |

|

| February 4, 2005: Marshall Heaton completes the block work. Center: main home, left: master bedroom wing, right: guest wing, rear: garage. |  |

|

| April 1, 2005: Top plates added, ready for foundation barriers then on to the beams and walls! |  |

|

February 4, 2005: Finished garage floor. This will house two cars, a workshop, bathroom, all of the the solar system electronics, a 32 megawatt 64 channel sound system :-), and other "experimental" electronic systems. In the rear is the home foundation. View is facing west, with ocean in view, but 5,415 feet down. |

|

|

| April 1, 2005: Another view (facing north) of the garage foundation ready for the top plates and walls. In the distance but blocked by the cedar on the left is the Palomar Observatory, home of the 200 inch Hale Telescope, a mere 2 miles away on that next ridge. You'll be able to see it from the dining room table, and several of the garage windows. Of course, we've been extra careful not to use intense lights on the exterior of the home, to protect the nighttime "light" environment. In fact, our eleven (11) exterior lights consume less than 75 watts of electricity in total. Once night falls, please don't point your flashlight at the telescope. |  |

|

May 17, 2005: The first walls go up in the garage, Dale Primus gracing the photo with his air conditioned "T-shirt-hat". The SIP panels are typically 8 feet wide and up to 22 feet in length. SIPs are a structural composite, with the three components (outer OSB, a foam core, typically expanded polystyrene, and inner OSB) working together for optimal strength, reduced air leakage, superior thermal insulation, and improved sound dampening. |

|

|

| May 17, 2005: The basement now waterproofed, the three massive beams that will support the first floor of the main section of the home are set in place. Doug Lande fearlessly walks a beam. You should see this man on a roof! |  |

|

| May 17, 2005: Need a small tractor dropped into the basement to finish grading before the cement floor is poured? No problem for Jay Whyte on the Cat Telehandler as Dale Primus watches. Jay is one good operator! |  |

|

| May 25, 2005: The four walls of the garage are up, and work starts on the second floor of the garage. The man in the white cowboy hat is Jay Whyte...get it? Contrary to popular folklore, Jay is not playing a violin, but rather a nail gun. I haven't heard him on the violin, but he plays a mean nail gun... |  |

|

May 26, 2005: Doug Lande (top center) setting timber with excellent assistance from Jay Whyte (top right), Mark Thompson (bottom left), and Alan Serry (bottom center, check out that Hawaiian shirt!). This team rocks! I ably assist by staying out of their way and instead work on wiring the garage. I am well trained in moving coulombs of electrons around, but not normally this many! I am more comfortable with nanoseconds and milliamps than hours and amps. |

|

|

| May 26, 2005: Its into the hole for one more concrete pour, this time the main home basement floor bringing the total basement foundation to 200,000 pounds of concrete. |  |

|

| May 26, 2005: Don Mendenhall (top right) and crew finishing off the basement floor after the last big concrete pour. The overhead concrete pumper can surely move a lot of material where you want it and quickly! |  |

|

| June 2, 2005: The windows and (glass) doors arrive and are stacked in and around the garage. e-Glass and dual pane for energy conservation and vented (for the altitude, so that they don't explode). |  |

|

| June 5, 2005: With the basement floor poured, sections of the main home floor are set in place on top of the three massive floor beams. Each floor section is about fifteen feet long, four feet wide, and ten inches thick. The floor beams are connected via splines with glue and large wood screws, some as long as a foot. The panels are also glued and screwed into the beams and top plates. The house will be very air and sound tight. |  |

|

| June 5, 2005: The first living room chair is set carefully in place, in front of one of the future main windows of course, for a view of the ocean below. The main floor sections are installed, the two wings remain to be done. |  |

|

| June 15, 2005: The main beam of the garage is set in place, followed by several of the roof panels. |  |

|

| June 17, 2005: Garage roof panels done! The garage stays reasonably warm in the winter (and cool in summer) because of the insulated SIP panels in the walls and roof, a huge benefit. |  |

|

| June 17, 2005: With the garage in the distance, the floor areas of the main home and wings are ready for placing of the home walls. |  |

|

| June 27, 2005: The first of the house walls go up! |  |

|

| July 3, 2005: Several large beams placed that will support the second floor; more home wall panels also in place, some one-story, some two-story. Flags ready and flying for the 4th of July. |  |

|

| July 3, 2005: Another view of the partially completed home with the detached garage in the background. |  |

|

| July 15, 2005: Walls up, main home beam in place. The main beam is 44 feet long, over one foot wide and two feet high, and weighs over 3,500 pounds. Next will be the roof panels, then the two wings of the home. |  |

|

| July 22, 2005: Roof of main section of home in place, with partial wing in place (left). The large opening will be the west facing very large window. |  |

|

| July 22, 2005: View into the main part of the home from immediately outside the very large west facing window. Second floor loft above. |  |

|

| August 8, 2005: View from the living room through the entry hall and into the guest wing. Alan Serry pouring over the plans while Jay's dog, Diamond, keeps an eye out for deer and wild turkeys. |  |

|

| August 8, 2005: Guest wing walls and roof panels all up! |  |

|

| August 19, 2005: West facing side of the home, with fascia being installed. |  |

|

| September 30, 2005: Garage doors installed, fascia completed, water / propane / electric conduits installed, inside plumbing underway. |  |

|

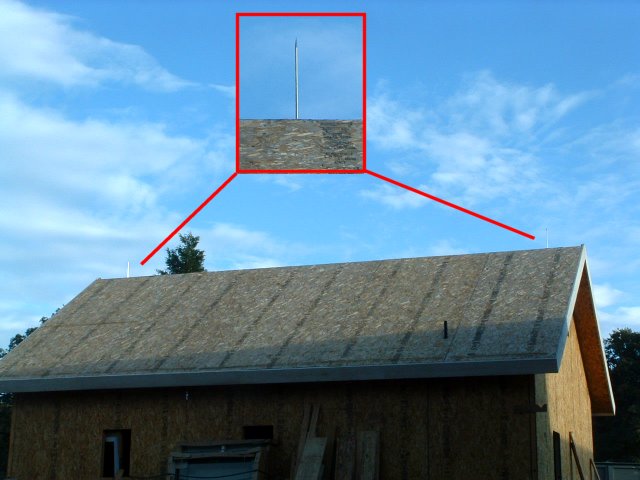

| September 30, 2005: Lightning rods, technology borrowed from Ben Franklin, with not a whole lot of improvements since, are place strategically on the home and garage roof peaks. Not a lot of people know much about lightning protection system design anymore, but the massive amount of electronics on the roof and in the home demand that I learn something about it. Unleashing between a billion and 10 billion watt seconds (joules) in several microseconds (millionths of a second) demands respect! Solar radiation powers our home, and the clouds too. |  |

|

| Two more heroes of construction: To the left, Ken Berthelot, mover of H2O and plumber extraordinaire. Ken runs pipes straight and does exceptionally neat work. He's working near where the ultra-efficient instant demand water heater will be installed. And to the right, Mike Kenny, mover of heated and cooled air, Mr. HVAC. Mike is installing three high efficiency air handing systems, one for each of the three home's sections. The furnaces are so efficient that the exhaust pipes are small PVC ("plastic" pipes). These guys are great to work with, just like the rest of our crew. |  |

|

| October 21, 2005: The home is wrapped with Tyvec, many of the windows installed, awaiting roofing cover. All three furnaces have been installed. |  |

|

| October 28, 2005: Waterproof underlayment for the roof, let it rain! |  |

|

| November 11, 2005: All windows and all but one wall of doors installed. Here looking through the smaller north end of the dining room with the Cat looking in... |  |

|

| November 11, 2005: Windows in place, getting ready for the fireproof exterior siding of the home. The fog has rolled in! |  |

|

| The utility building, housing the well head, water pump, and propane emergency generator. |  |

|

| November 25, 2005: Application of fiber cement siding that provides better dimensional stability than wood, is impervious to wood-boring insects, and, most importantly, has a Class 1 (A) Fire Rating. |  |

|

| December 3, 2005: Home is "closed up", siding work well underway! |  |

|

December 3, 2005: We're surprised by a 24 foot tall tree inside our 24 foot tall home! A gift from the construction crew, Alan Serry presiding. From left: Peggy Hamerly, Chris Serry, and Alan Serry, the ring leader. At left: bottom 12 or so feet; at right: top 12 or so feet. |

|

|

| January 13, 2006: Metal garage and home roofs with flexible photovoltaic laminates ("solar cells") set in the trough of each metal "pan". The home is off the electrical grid, completely self sustaining. Monday January 9th, 2006 we start generating our own power! |  |

|

| January 13, 2006: 16 high capacity gel-cell batteries provide emergency and night time power. Inset (above left): Outback inverters mounted in the electronics vault for converting 48 VDC from the panels to 230 / 115 VAC, charging the high capacity batteries, and remotely controlling the 12KW emergency generator. Power is generated for the home by solar panels and stored in batteries, with a12KW backup generator on hand. We don't plan to use the generator. It gets turned on once/month, just for emergency checks and circulating the engine oil. |  |

|

| January 13, 2006: Almost all of the siding and external trim work is done. Now we start to focus on the interior. Just in time! Snow is expected tomorrow night. |  |

|

| April 7, 2006: While the interior walls are being plastered, construction of the rear deck is underway. It will be sheathed in Amerideck material, the only Class-A fire rated decking manufactured at the time. |  |

|

| Approximate same-view comparison from late spring 2004 (above, still clearing the land) and early spring 2006 (below, house not yet completed). |  |

|

| May 5, 2006: Our most excellent wall crew, now into paint mode. Poncho, Bill Druliner, Art, and Terry Cameron...all smooth with the plaster and paint! |  |

|

| May 5, 2006: Standing in the living room looking upward, testing of several colors on the walls below. |  |

|

| June 6, 2006: Dale Boettcher placing stone in one of the bathroom shower/tub areas. |  |

|

| June 6, 2006: Portion of a 50 foot cedar tree (kindly provided by Robert Carlyle) being cleaned by Doug Lande (one of our many mountain craftsmen) to form what will become the fireplace mantle (cleaned and shaped below for further drying). |  |

|

| July 22, 2006: Stonework and cedar mantle in place for the fireplace, wood flooring installed. |  |

|

| July 22, 2006: Kitchen cabinets and island almost completed with wood floor in place. Still need to add crown molding, appliances, and countertops. |  |

|

| July 22, 2006: A view of the new wood floor taken from the second floor. |  |

|

| August 19, 2006: Granite countertops and back splashes in place, with some appliances installed. |  |

|

November 28, 2006: The Department of Planning and Land Use approves a "Certificate of Occupancy". We thought it would never happen....read more about it here. I am now able to move furniture into the home. To the right, a very large custom farm house table and bench that I made for the home, with antique chairs that we refinished. My younger son Tim helped me drag the table in, I estimate it weighs about 350 pounds or more. |

|

|

| A side table I made to match the larger dining room table (above). The acorns and wild flowers are from the property. |  |

|

| Workshop in the garage. |  |

|

| Opposite workshop in the garage. |  |

|

| December 19, 2006: After our first snowfall! The rear of the home, facing south-east. |  |

|

| The front of the home, with the large 2-story west facing windows. |  |

|

| Ice on the trees everywhere... |  |

|

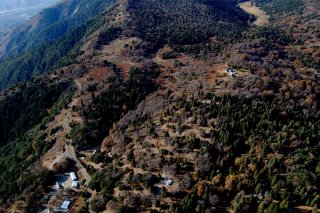

| Aerial view of the home close-up: Click on image to get a large version. |  |

|

| Here are some distant aerial views of the home: Click on a thumbnail to see a larger version. |

|

|